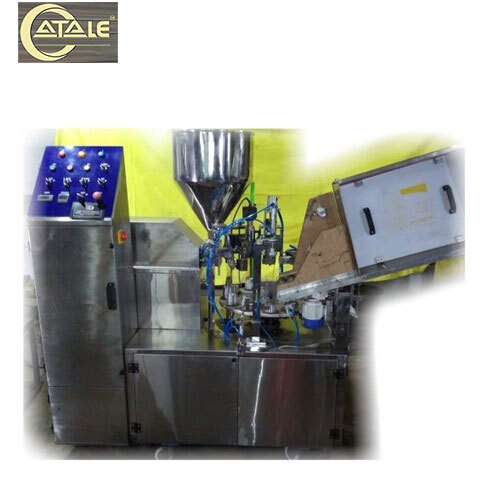

Table Top Tube Filling And Sealing Machine

Price 175000 INR/ Piece

Table Top Tube Filling And Sealing Machine Specification

- Model No

- TTFS-01

- Production Capacity

- 10-30 tubes/min

- Motor Power

- 0.18 kW

- Cooling System

- Air Cooling

- Accuracy

- 1%

- Lubricating System

- Self-lubricating

- Frame Type

- Stainless Steel Frame

- Control System

- Button Control Panel

- Voltage

- 220 V

- Plastic Processed

- Plastic/Laminated Tubes

- Operating Temperature

- 5C 40C

- Features

- Compact Design, Easy Operation, Quick Changeover

- Drive

- Pneumatic

- Noise Level

- < 65 dB

- Power Rating

- 0.5 kW

- Machine Type

- Tube Filling & Sealing

- Frequency

- 50 Hz

- Product Type

- Table Top Tube Filling And Sealing Machine

- Technology

- Semi-Automatic Pneumatic Technology

- Power Source

- Electric

- Operating Type

- Manual/Automatic

- Power

- 500 W

- Pressure

- 0.4-0.6 MPa

- Surface Treatment

- Stainless Steel Finish

- Dimension (L*W*H)

- 600 x 400 x 650 mm

- Weight (kg)

- 60 kg

- Color

- Silver

- Usage & Applications

- Filling and sealing of plastic and laminated tubes for pharmaceutical, cosmetic, and food industries

- Packaging Type Supported

- Plastic and Laminated Tubes

- Electrical Protection

- Fuse Protection

- Changeover Time

- <10 minutes

- Tube Diameter Range

- 1050 mm

- Compressed Air Requirement

- 0.6 MPa

- Filling Volume Range

- 5250 ml

- Safety Features

- Emergency Stop, Overload Protection

- Sealing Method

- Hot Air Sealing

- Tube Length Range

- 50200 mm

- Material of Construction

- SS304

- Validation Certificate

- GMP Compliance

- Maintenance

- Tool-free for cleaning and changeover

- Hopper Capacity

- 25 liters

- WorkingSpeed

- Adjustable

- Number of Filling Heads

- Single

- Dosing System

- Pneumatic Driven Piston Filling

- Level of Automation

- Adjustable Semi-Automatic

- Display

- Digital Timer

Table Top Tube Filling And Sealing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 2 Pieces Per Month

- Delivery Time

- 30 Days

About Table Top Tube Filling And Sealing Machine

We deliver Table Top Tube Filling And Sealing Machine machine which is known for offering trouble- free and cost- effective performance. To seal different type of tubes, this machine is featured with rotating disc and interchangeable tube holding socket. Easy to operate and use, our provided machine has rugged construction and high durability. Also .it is available with various technical specification in addition, this highly efficient Table Top Tube Filling And Sealing Machine is durable and reliable.Efficient Tube Filling and Sealing for Every Industry

Designed to streamline tube packaging, this machine supports plastic and laminated tubes, making it ideal for pharmaceuticals, cosmetics, and food. With its user-friendly control panel, quick changeover under 10 minutes, and adjustable working speed, users experience excellent workflow efficiency and minimal downtime.

Robust Safety and Maintenance Features

Safety is prioritized with emergency stop, overload, and fuse protections. The machine's tool-free cleaning and changeover system enables rapid maintenance while preserving operational integrity. Operators benefit from its self-lubricating mechanism and air cooling system.

Precision and Compliance Assured

Delivering accurate tube filling with a pneumatic driven piston system, this device maintains 1% dosing accuracy. Its SS304 stainless steel structure ensures hygiene and compliance with GMP standards, suited for highly regulated production environments.

FAQ's of Table Top Tube Filling And Sealing Machine:

Q: How does the hot air sealing process work on this tube filling and sealing machine?

A: The machine uses a hot air sealing method wherein heated air melts the ends of plastic or laminated tubes before compressed pressing forms a hermetic seal, ensuring leak-proof packaging suitable for various industries.Q: What are the benefits of adjustable semi-automatic operation in this machine?

A: Adjustable semi-automatic operation allows the user to switch between manual and automatic filling modes, providing flexibility for varying production demands and enhancing overall process control.Q: When is it necessary to change over between different tube sizes or products, and how quickly can this be accomplished?

A: Changeover is needed when switching to different tube sizes or products. With its tool-free design, the process is straightforward and can be completed in less than 10 minutes, minimizing downtime.Q: Where can this machine be installed and what is required for setup?

A: Its compact tabletop design makes it suitable for labs, small-scale production lines, and industrial settings. Installation requires access to a 220 V electric supply, compressed air at 0.4-0.6 MPa, and adequate workspace for its 600 x 400 x 650 mm dimensions.Q: What is the process for tube filling and sealing on this equipment?

A: Tubes are manually loaded; the pneumatic piston fills each tube with precise volume. Each filled tube is then sealed using hot air, cooled by air cooling, and ejected, ready for packaging.Q: How is cleaning and maintenance performed on the machine?

A: Routine cleaning and changeover are tool-free, enhancing convenience and speed. The machine's self-lubricating system further reduces the need for frequent manual maintenance, promoting smooth operation.Q: What advantages does this machine offer over fully manual filling methods?

A: Compared to manual methods, this semi-automatic machine delivers faster throughput (10-30 tubes/min), higher accuracy (1%), consistent sealing, improved safety, and compliance with GMP standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sealing Machine Category

Band Sealer Machine

Price 250000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Product Type : Filling Machine

Operating Type : Automatic

Power Source : Electricity

Warranty : 01 year

Automatic Tray Sealing Machine

Price 25000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Product Type : Filling Machine

Operating Type : Automatic

Power Source : Electricity

Warranty : 01 year

Fully Automatic Tube Filing Machine

Price 750000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Filling Machine

Operating Type : Automatic

Power Source : Electricity

Warranty : 01 year

Semi-automatic Cup sealing machine (Rotary)

Minimum Order Quantity : 1 Piece

Product Type : Filling Machine

Operating Type : Semi Automatic

Power Source : Electricity

Warranty : 01 year

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS